Technologies

GEM Fleet Management Software

Saritasa essentially provides us with staff augmentation. They offer the whole package of set up, development, maintenance, and upkeep — they take care of the whole lot. Communication is excellent, and they’ve met deadlines. Overall, they stay true to their word.

Hoa ChaOperations Manager at GemOne

Their Challenge

For large warehouses, fleet management is critical. A loss in productivity can result in higher operating costs and loss of revenue. There’s no reason the same advancements that have helped healthcare, transportation, and so many more industries couldn’t be applied to fleet and machine management.

GEM wanted to apply their 50 years of experience in industrial equipment and their 20 years of experience with digitization to create a revolutionary telecommunication technology. They just needed the right technology partner to get started.

Our Solution

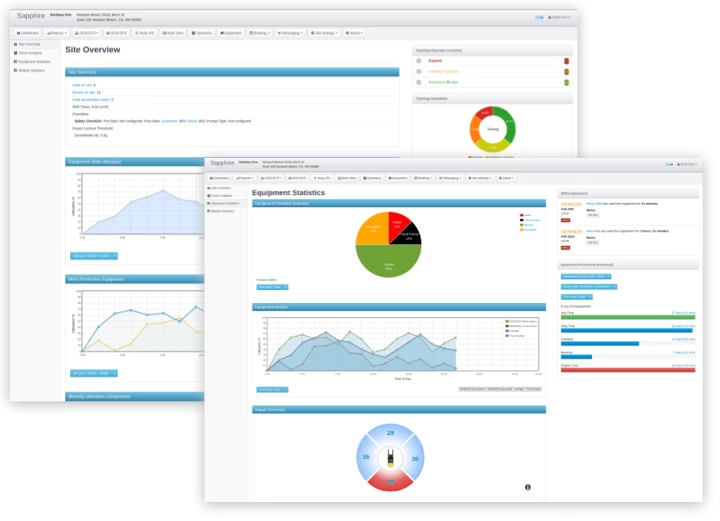

Saritasa helped GEM develop advanced fleet management by incorporating hardware and software for a robust, game-changing system. The GEM systems track and trace machines in real-time, provide incredible security and safety solutions, and optimize for productivity and efficiency. Operators utilize tablets that pinpoint their exact location and continually send data to the main system.

Our Approach

What Saritasa Did

Real-Time Data

At any given moment, an admin can pinpoint the exact location of any machine in their fleet. This is made possible by a robust system of beacons placed around the warehouse or worksite that ping the distance between each sensor and the machine’s sensor.

Big Data

The GEM system collects and stores a massive amount of data every second. Sensors are continually tracking the real-time location of machines and sending that information to the database. Our team refined and indexed the database for optimized management and reporting. The database was built using PostGresSQL.

Route Optimization & Collision Avoidance

The real-time data allows the system to optimize the most efficient routes from point A to point B in a warehouse. Route optimization increases machine efficiency, productivity, and can directly impact the company’s bottom line. Collisions are also avoided by alerting the user of nearby hazards, such as walls or other machines. If a collision does occur, an admin is notified and can quickly schedule maintenance or repair to reduce downtime.

Firmware Development

Our team developed firmware to communicate directly with GEM’s hardware devices, from the beacons to the tablets used by the machine operators.